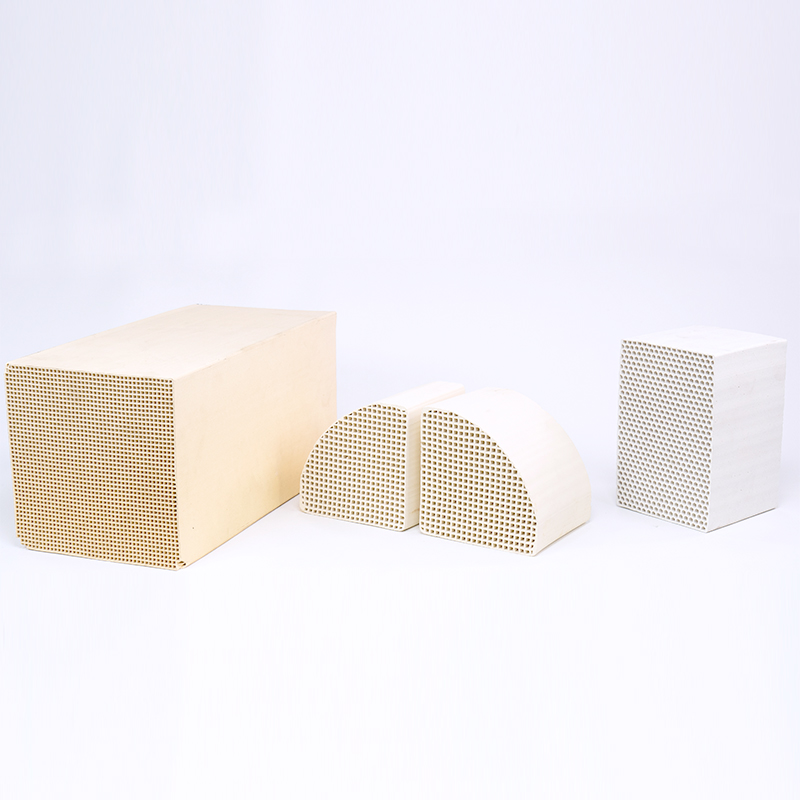

RTO - Ceramic Kutentha Kutentha kwa Honeycomb

Ntchito

1.Kuchepetsa kutayika kwamafuta a gasi wotulutsa mpweya, ndikuwongolera magwiridwe antchito amafuta kuti apulumutse mphamvu ngati.

2.Onjezani kutentha koyaka potengera chiphunzitso, sinthani kuyatsa kwamlengalenga, kukumana ndi kutentha kwamphamvu kwa zida zotenthetsera kukulitsa mafuta otsika kwambiri a calorific, makamaka kugwiritsa ntchito ng'anjo zamoto, kupititsa patsogolo mphamvu yamafuta a calorific komanso kuchepetsa kutulutsa kwa gasi wa malasha otsika kwambiri.

3.Sinthani mawu osinthira kutentha m'malo opangira moto, onjezerani kutulutsa kwa zida, kukulitsa mtundu wazinthu ndikuchepetsa kubwezanso zida.

4.Kuchepetsa kutulutsa mpweya kwa zida zotenthetsera, kuchepetsa kuipitsidwa kwa mpweya ndikuwongolera chilengedwe.

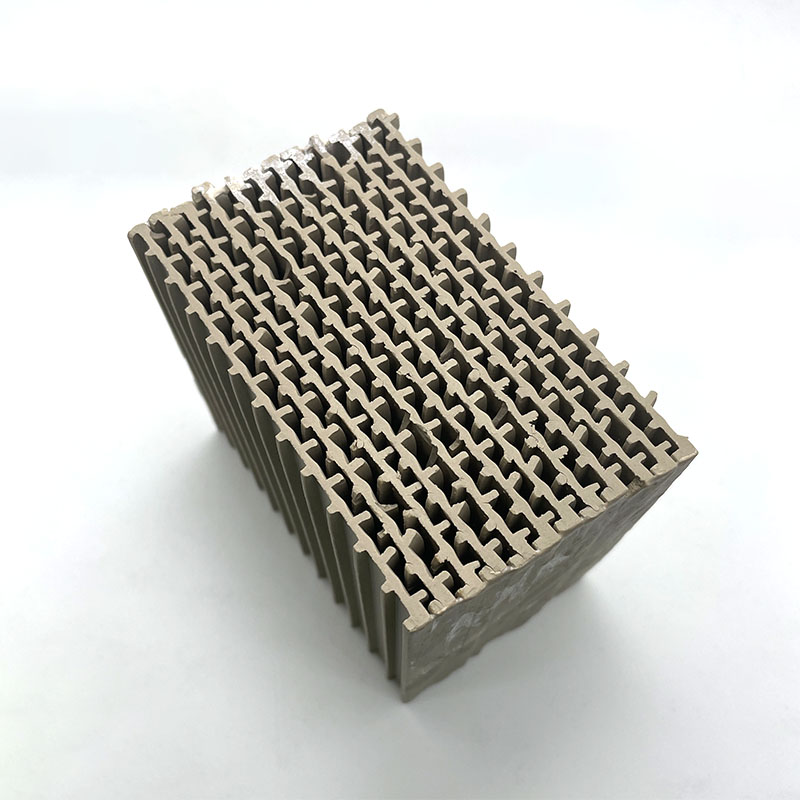

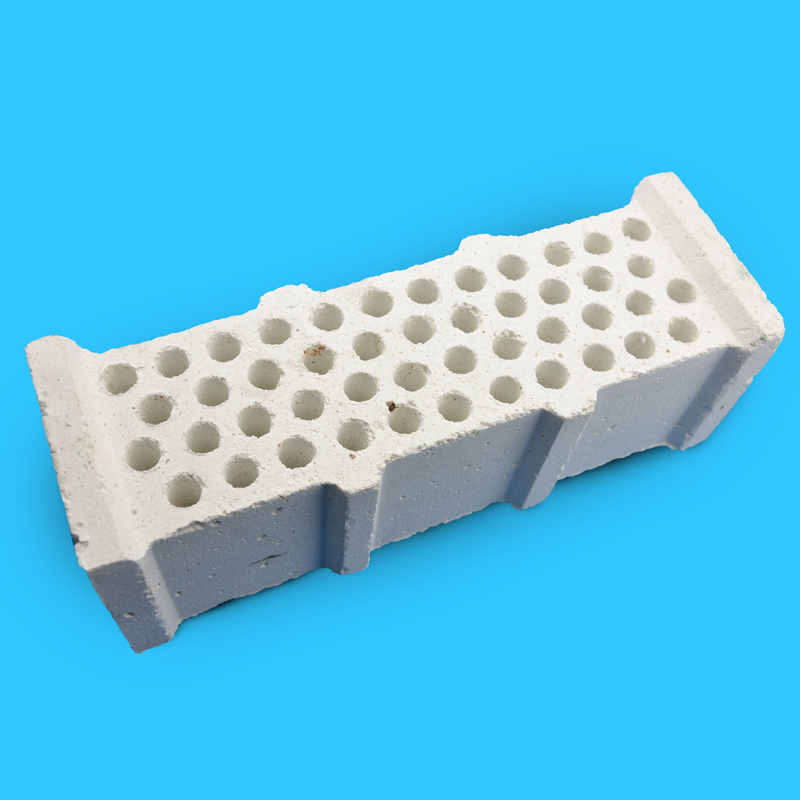

Makhalidwe

Makhalidwe a zisa za ceramic regenerator ndi motere: ali ndi kutentha pang'ono, kutentha kwakukulu kwapadera, malo okwera kwambiri, kutsika kwapansi, kutsika kwa kutentha, kutsekemera kwabwino kwa kutentha, kutentha kwa kutentha, ndi zina zambiri. Chifukwa chake, m'mafakitale azitsulo ndi mankhwala, amagwiritsidwa ntchito ngati HTAC, pomwe tikuphatikiza kukonzanso kutentha kwa mpweya, kuyaka kothandiza kwambiri ndi kuchepetsa NOx. Zimakhala zopulumutsa mphamvu zenizeni ndikuchepetsa Nox.

Zida: Alumina, Dense Alumina, Cordierite, Dense Cordierite, Mullite, Corundum Mullite ndi ena

Kugwiritsa ntchito

Ceramic ya uchi ndiye chinsinsi komanso chigawo chachikulu chaukadaulo wosungira kutentha kwambiri (ukadaulo wa HTAC). Zakhala zikugwiritsidwa ntchito kwambiri m'malo osiyanasiyana otenthetsera zitsulo, ng'anjo zoyatsira moto, ng'anjo zotenthetsera kutentha, ng'anjo zopangira, ng'anjo zosungunuka, zowotcha zaladle / tundish, ng'anjo zonyowa, zoyatsira machubu owala, ndi ng'anjo zamtundu wa belu mumakampani opanga zitsulo. Ng'anjo, ng'anjo yowotcha mpweya wotentha; ng'anjo zosiyanasiyana za ceramic ndi ng'anjo zosiyanasiyana zamagalasi m'makampani omanga; ng'anjo zosiyanasiyana zotenthetsera ma tubular, ng'anjo zosweka ndi ng'anjo zina zamafakitale mumakampani a petrochemical.

Zofotokozera

100x100x100, 100x150x150, 150x150x150, 150x150x300mm ndi ena

Chiwerengero cha mabowo: 25x25, 40x40, 43x43, 50x50, 60x60 ndi ena

Dimension

| Dimension (mm) | Maselo (N×N) | Kuchulukana kwa Ma cell (CPSI) | Kukula kwa Channel (mm) | Kukhuthala kwa khoma lamkati (mm) | Free Cross Section (%) |

| 150 × 150 × 300 | 20 × 20 | 11 | 6.00 | 1.35 | 64 |

| 150 × 150 × 300 | 25 × 25 pa | 18 | 4.90 | 1.00 | 67 |

| 150 × 150 × 300 | 32 × 32 pa | 33 | 3.70 | 0.90 | 63 |

| 150 × 150 × 300 | 40 × 40 pa | 46 | 3.00 | 0.70 | 64 |

| 150 × 150 × 300 | 43 × 43 pa | 50 | 2.80 | 0.65 | 64 |

| 150 × 150 × 300 | 50 × 50 | 72 | 2.40 | 0.60 | 61 |

| 150 × 150 × 300 | 59x59 pa | 100 | 2.10 | 0.43 | 68 |

Chemical Composition

| Kanthu | Cordierite | Mullite | Alumina Porcelain | High Alumina Porcelain | Corundum |

| Al2O3 | 33 | 65 | 54 | 67 | 72 |

| SiO2 | 58 | 30 | 39 | 23 | 22 |

| MgO | 7.5 | <1 | 3.3 | 1.7 | <1 |

| Ena | 1.5 | 14 | 3.7 | 8.3 | 5 |

Zakuthupi

| Kanthu | Cordierite (Porous) | Mullite | Alumina Porcelain | High Alumina Porcelain | Corundum | |

| Kachulukidwe (g/cm3) | 1.8 | 2.0 | 1.9 | 2.2 | 2.5 | |

| Kumwa madzi (%) | 23 | 18 | 20 | 13 | 12 | |

| Coefficient of Thermal Expansion(×10-6K-1) (20~800℃) | ≤3.0 | ≤6.0 | ≤6.3 | ≤6.0 | ≤8.0 | |

| Kutentha Kwapadera (J/Kg.K) (20~1000℃) | 750-900 | 1100-1300 | 850-1100 | 1000-1300 | 1300-1400 | |

| Thermal Conductivity (W/mk) (20 ~1000℃) | 1.3-1.5 | 1.5-2.3 | 1.0-2.0 | 1.5-2.3 | 5; 10 | |

| Max. Nthawi yogwira ntchito.(℃) | 1200 | 1400 | 1300 | 1400 | 1650 | |

| Axial crushing mphamvu (MPa) | Zouma | ≥11 | ≥20 | ≥11 | ≥22 | ≥25 |

| Kumiza | ≥2.5 | ≥2.5 | ≥2.5 | ≥2.5 | ≥2.5 | |