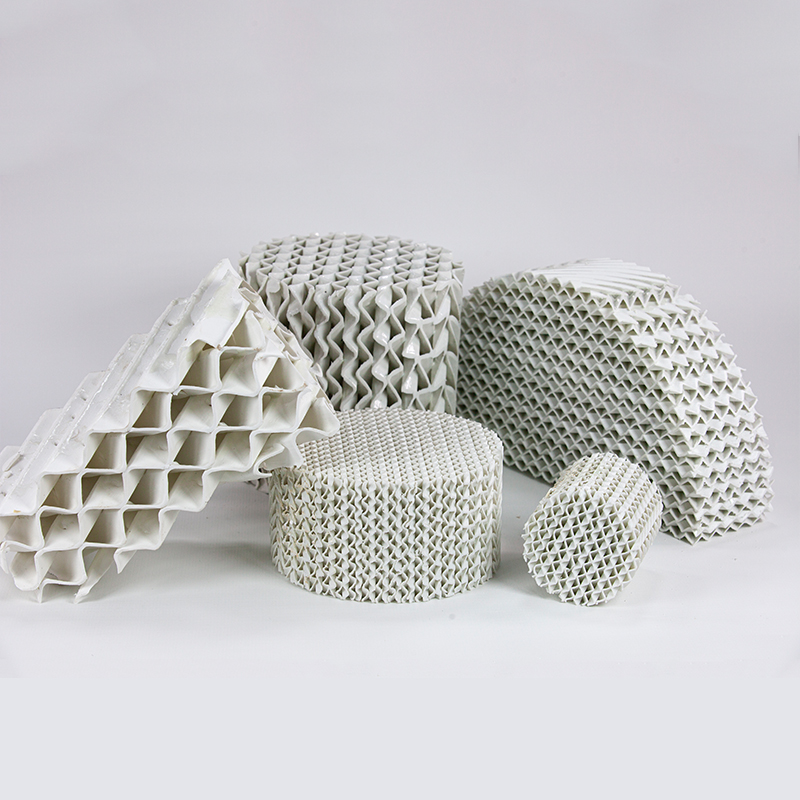

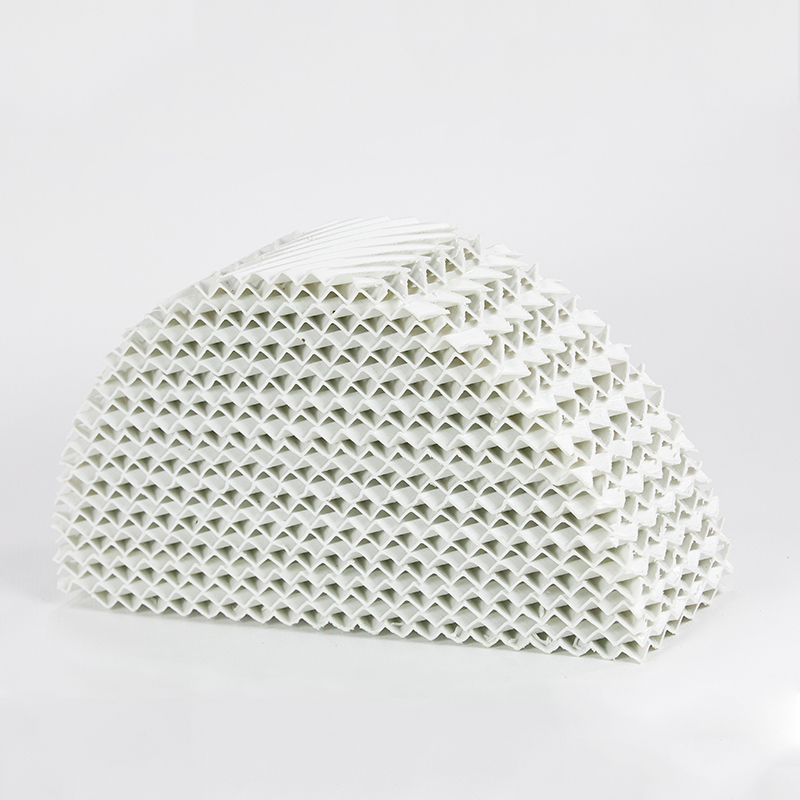

Ceramic Structured Packing yokhala ndi mtundu wa 125Y & 250Y

Chifukwa cha mawonekedwe apadera a ceramic, ntchito yabwino ya hydrophilic, pamwamba pake imatha kupanga filimu yamadzi yopyapyala ya chipwirikiti yopendekeka komanso njira zowawa zimatha kulimbikitsa mpweya koma osayimitsa mafananidwe ndi mpweya wodzaza zitsulo ungapangitse kulongedza kwa ceramic, komanso kukana kwake kwa dzimbiri, kusagwira ntchito kwazitsulo zachitsulo sikungafanane. kutenthedwa, kuphatikizika, ndi coking.This mankhwala amapangidwa ndi apamwamba mankhwala zadongo dongo yaiwisi processing ndi kukhala, kugonjetsedwa ndi kutentha kwambiri ndi kuthamanga kwambiri, kukhazikika kwa mankhwala ndi mphamvu mkulu, ndi chonyamulira abwino kuthandiza mitundu yosiyanasiyana ya catalysts.

Chemical Analysis

| Kupanga | Mtengo |

| SiO2 | ≥72% |

| Fe2O3 | ≤0.5% |

| CaO | ≤1.0% |

| Al2O3 | ≥23% |

| MgO | ≤1.0% |

| Zina | 2% |

Katundu Wakuthupi

| Mlozera | Mtengo |

| Kukoka kwapadera (g/cm3) | 2.5 |

| Kumwa madzi (wt%) | ≤0.5 |

| Kukana kwa Acid (wt%) | ≥99.5 |

| Kutaya pakuwotcha (wt%) | ≤5.0 |

| Max. Kuwotcha (℃) | 800 |

| Kuphwanya mphamvu (Mpa) | ≥130 |

| Kuuma kwa Moh (Sikelo) | ≥7 |

Tsiku laukadaulo

| Spec. | Malo enieni (m2/m3) | Kachulukidwe kachulukidwe (kg/m3) | Chiwerengero chopanda kanthu (%) | Obl. ngodya | Kutsika kwamphamvu (mm Hg/m) | Theo. Mbale (m-1) | Dipo la Hydraulic (mm) | Katundu wamadzimadzi (m3/m2h) | Max. Factor m/s (Kg/m3)-1 |

| 125y pa | 125 | 320 | 90 | 45 | 1.8 | 1.8 | 28 | 0.2-100 | 3.0 |

| 250 Y | 250 | 420 | 80 | 45 | 2 | 2.5 | 12 | 0.2-100 | 2.6 |

| 350 Y | 350 | 470 | 78 | 45 | 2.5 | 2.8 | 10 | 0.2-100 | 2.5 |

| 450y pa | 450 | 520 | 72 | 45 | 4 | 4 | 7 | 0.2-100 | 1.8 |

| 550 Y | 550 | 620 | 74 | 45 | 5.5 | 5-6 | 6 | 0.18-100 | 1.4 |

| 700 Y | 700 | 650 | 72 | 45 | 6 | 7 | 5 | 0.15-100 | 1.3 |